Denkendorf, September 2, 2021 – The conversion of used trucks for distribution and long-distance traffic to electric drives promotes the sustainable future of the logistics and transport industry and efficiently supports the emission-free use of commercial vehicles. As a leading technology company, pepper motion GmbH is now presenting the product plans and strategy for its new, freely scalable electrification kits in the larger than 7.5 t truck sector according to the international automotive industry’s highest functional safety standards. The highly energy-efficient, modular battery-electric drive system can be used to convert different types of trucks for different business models with different application scenarios.

The first versions of the battery-electric etrofit® drive system for series production will be available as early as spring 2022. The aim is to install a total of more than 1,000 electrification kits in converted and new vehicles by 2024. The etrofit® kit will also be made available as a Tier 1 solution to body-makers and OEMs so that they can integrate it into new vehicle developments or existing vehicle series and offer zero-emission new vehicles to their customers without high development costs. pepper calculates a total of over 20,000 units sold in the truck sector by 2030, of which over 6,000 units alone will be as Tier 1 kits for vehicle manufacturers in various European markets.

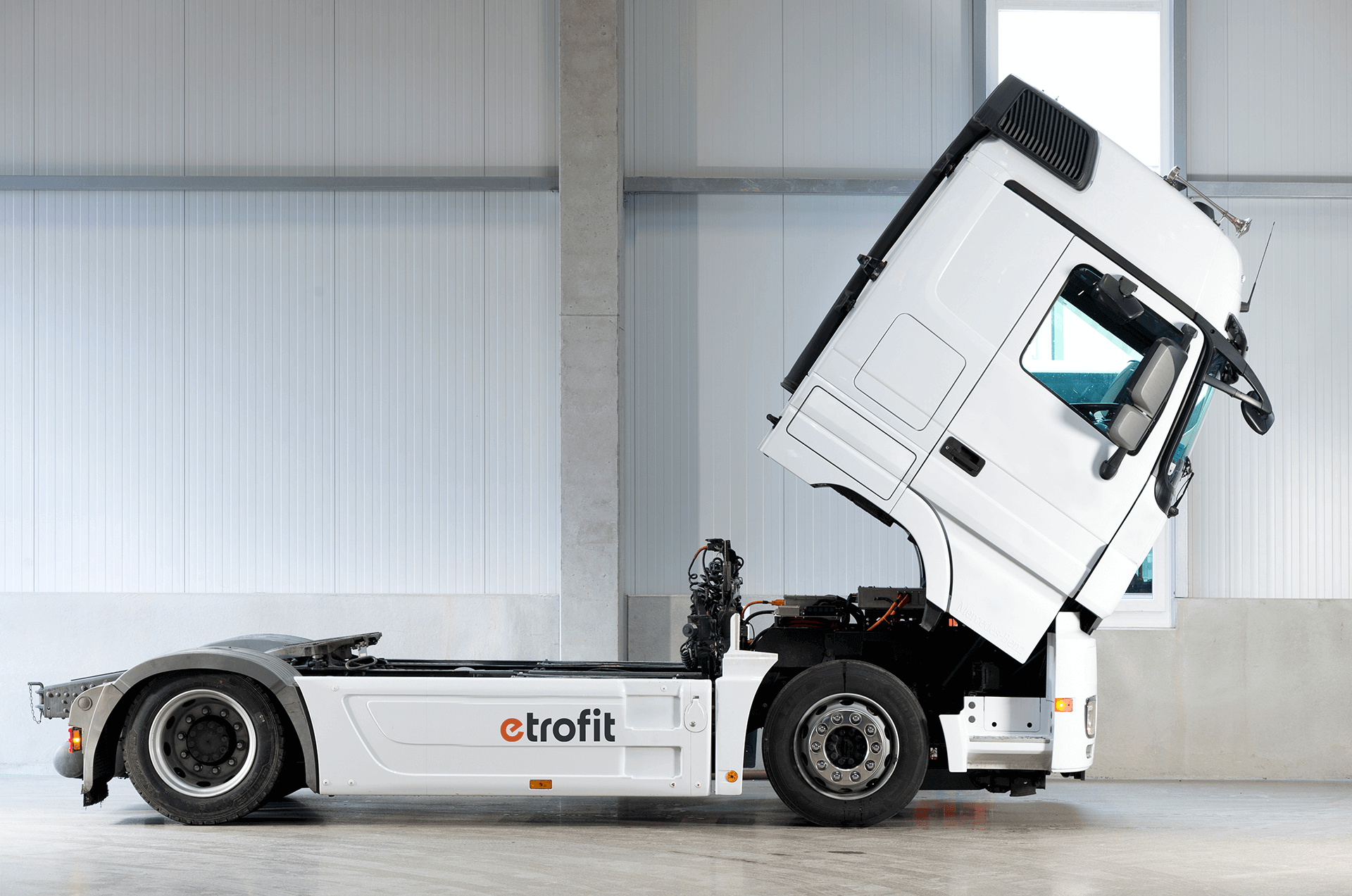

As a manufacturer and developer, pepper electrifies its customers’ own vehicles, provides conversion companies and OEMs with complete etrofit® kits, or end customers with already converted vehicles. The kit includes all the components needed to convert a vehicle or for a new vehicle build. From the battery, electric motor, auxiliary components, and control unit with system software developed in accordance with ISO 26262 for functional safety, to the interface to the (existing) vehicle, modular and fully validated complete packages are available. The technological heart of the drive system is the company’s own system architecture software, which currently puts pepper several years ahead of the competition. The battery capacity of the electric drive system can be scaled up from the smallest version with 120 kWh to 240, 360 or even over 700 kWh net, depending on the application scenario. Conversion instructions and documentation for truck models with high market potential, in combination with partner training, enable conversion and maintenance by certified partners at the customer’s premises, generating increased local value creation at the same time.

pepper essentially provides electrification solutions for trucks larger than 7.5 t; the first conversion products will be available for the Mercedes Actros and Atego models as early as spring 2022. Models from MAN and IVECO will be electrified in series production from 2023. “In principle, it is possible to electrify any vehicle model,” explains Robert Reisenauer, Head of Sales and Marketing at pepper motion GmbH. “As soon as customers want to convert a model in relevant quantities that we haven’t done before, we estimate a development time of twelve months until the project is ready for series production.” If products are available in series production, they can be delivered within five months of the order.

The breakthrough in the electrification of commercial vehicles is assisted by the German Federal Ministry of Transport’s (BMVI) funding guidelines for commercial vehicles with alternative drive systems, which are currently approved by the European Commission. These provide an attractive funding program for battery, fuel cell and (catenary) hybrid electric vehicles, corresponding refueling and charging infrastructure, and feasibility studies, and creates incentives for transport companies that want to switch to climate-friendly commercial vehicles and avoid penalties under the Clean Vehicles Directive, which came into force in August. Electrification kits for conversion are now given equal status to new vehicles in terms of funding. Pepper is the only manufacturer in the conversion segment that fully meets the catalog of criteria for high-quality conversion and functional safety established by the BMVI Task Force.

“Starting in the planning phase, it is immensely important to focus on the quality aspect of the solutions offered,” Reisenauer says. “For safe and reliable vehicle use, the catalog of criteria with minimum standards* initiated by the BMVI provides helpful support for decision-making. With our electrification solutions for commercial vehicles, fleet operators will gain an important tool for designing an emissions-free vehicle fleet and sustainable climate protection.”

*https://www.bmvi.de/SharedDocs/DE/Anlage/StV/ergebnisbericht-umruestung-nutzfahrzeuge.pdf

Context

Technology trials in pre-series vehicles

Focusing on the conversion of trucks larger than 7.5 tons, developer and manufacturer pepper motion GmbH put its first battery-powered electric truck for distribution transport of up to 26 tons on the road at the beginning of May 2021. The pre-series vehicle, which is undergoing practical trials in cooperation with the Austrian logistics firm Herbert Temmel GmbH, provides valuable information regarding the use and reliability of the vehicle in long-term trials in real customer operations. The pre-series vehicle with road approval is currently being used to validate the design in customer use and gain valuable insights for further development into series production.

Sustainable and environmentally friendly

Purely battery-electric powertrains are ideally suited for applications in local and distribution traffic, factory traffic or special urban applications. The etrofit® kits for diesel vehicles, developed according to OEM standards, offer series solutions for a quick introduction into electromobility for commercial vehicles in distribution and long-distance traffic, as well as for special vehicles (e.g. municipal vehicles). Existing vehicles are thus given an economical extension of their service life and an environmentally friendly “second life” as an electric vehicle. “Densely populated areas benefit from noise reduction, and on the short distances in urban areas, the battery-powered electric drive system perfectly delivers its economic advantages over old-fashioned diesel vehicles with very high consumption and wear.”

About pepper motion GmbH:

pepper – electrifying transportation! The privately financed German company with its headquarters in Denkendorf and offices in Garching near Munich employs around 75 people. pepper is also present at four additional sales and development locations in Austria, Italy, Poland, and Bulgaria.

As the first digital OEM worldwide (without its own warehousing and manufacturing), pepper offers innovative solutions for the electrification (retrofitting) of used and new commercial vehicles such as trucks in distribution transport, buses in local public transport (LPT), and municipal vehicles. pepper is ISO 9001 certified and as such is the only supplier of conversion solutions to ensure operational safety according to international automotive industry standards such as ISO 26262 for functional safety. A network of international partners guarantees service and availability across Europe.

With its holistic approach to telematics, charging infrastructure, fleet management and autonomous driving, the company designs quickly implementable and cost-efficient solution packages for sustainable mobility transformation and a “second life” for existing commercial vehicles. They effectively support the implementation of the CO2 reduction targets in accordance with the European Green Deal Agreement and the Clean Vehicles Directive, which will come into force in 2021.

pepper was awarded the German Mobility Prize (2018) and the Austrian VCÖ Mobility Prize (2019), as well as being voted one of the top 50 start-ups in Europe in the field of mobility (2020, EUSP).

Additional information: www.peppermotion.com

Press Contact:

360°communications GmbH

E-Mail: pepper@360communications.de

Tel: +49 89 5436994 00

Download PDF